Another green infrastructure marvel in aviation sector...

By - Jeyaraj Kalirajan, Vamshi Ranga, T M Shilpa

“…simplicity means to choose ways of living that touch the Earth more lightly and reduce our ecological footprint”_ Duane Elgin”

The carbon footprint of aircraft is just 2.2% of world energy consumption. However, where does this carbon footprint in the form of greenhouse gases end up? Nearly 10% of the carbon footprint is projected near the ground. Approximately 90% of greenhouse gases are injected directly into the stratosphere, which plays a crucial role in protecting the environment and stabilising the climate. The catastrophic effect of direct pollution turns the air composition into a disaster for climate change.

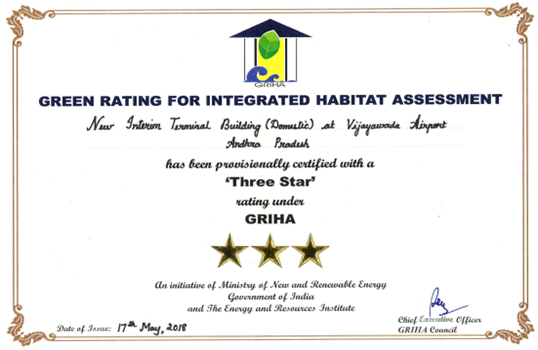

International Civil Aviation Organisation (ICAO) requires that the aviation industry reduces its carbon footprint through clean technologies and policy tools. The Vijayawada Airport also contributed to this by going green through their New Interim terminal (Domestic) Building in Andhra Pradesh by achieving GRIHA 3 Stars.

GreenTree Global, based in Delhi NCR, having its own vision to help develop Net Zero projects in India and around the world, played a critical role in providing timely recommendations and ensuring the Airport design to meet its target.

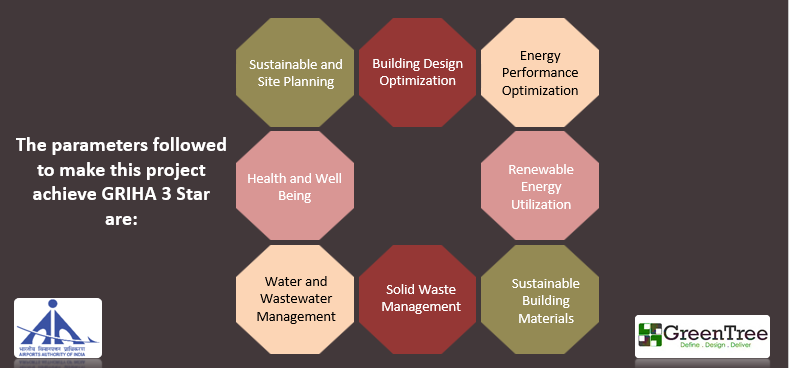

Green strategies taken by the New Interim Terminal (Domestic) Building are…

SUSTAINABLE AND SITE PLANNING

• Top soil was preserved and mulched with organic matter to maintain its fertility and was later reused for landscaping.

• Air pollution control measures such as site barricading were implemented during construction to contain pollution.

• Out of 4 existing mature trees, 2 mature trees were preserved and in addition compensatory plantation of

254 trees was done on site.

SAFETY AND SANITATION FACILITIES FOR THE CONSTRUCTION WORKERS-

• The project ensured that the safety procedures were taken care through safety hats for the workers, safety shoes, safety barricading, along with clean water facilities, toilet accommodations for the workers and family.

IMPROVING AIR POLLUTION DURING CONSTRUCTION

• The team took necessary measures to reduce the air pollution caused during the construction by putting 3m high barricading, use of dust suppression, provision of wheel washing, sprinkling of water, adequate DG stack height.

REDUCING WATER CONSERVATION

• Reduction of 64.4% from the GRIHA base case has been demonstrated in building water use by installing

water efficient flush systems and flow fixtures.

• STP with 200 KLD capacity is proposed at site with MBBR technology process to treat 100% of the waste

water generated at site.

• Water stored in temporary sedimentation tank at site was used for curing during construction.

ENERGY OPTIMIZATION

For achieving visual comfort:

• 54% of the habitable spaces in the building are day lit and meet the daylight factors as per GRIHA

requirements.

• 36% of the habitable spaces in the building are day lit and meet the daylight factors as per GRIHA.

• Longer sides of most of the building blocks are facing

• Eastern and Western direction.

For achieving thermal comfort:

• AAC blocks and rock wool insulation was considered for external wall & roof respectively to maintain the

thermal comfort within the building.

• Water cooled screw chillers and VRF system have been installed to achieve cooling load & thermal

comfort of the project.

• Longer sides of most of the building blocks are facing Northern and Southern direction.

INTEGRATING RENEWABLE ENERGY

• 15kW solar PV system has been installed, which will offset 8.37% of the total internal lighting energy

consumption requirement

SUSTAINABLE BUILDING MATERIALS

• The embodied energy of the non-structural applications has been reduced by 8.48% by using solid AAC block and fly ash bricks.

• Indoor air quality has been maintained by using 100% interiors finishes with no/low VOC content (adhesives and sealants).

Salutations

Until policy and stakeholders work together to design and implement a sustainable plan for preserving the natural resources and a working aviation industry to accommodate the clean technologies. The industry surely has a responsibility to reduce its carbon footprint like Vijayawada Airport and many others by implementing strategies that will result in changing the infrastructure into green and carbon neutral (going forward).