Navigating the intricacies of the Super Efficient Ceiling Fan

The fundamental components of ceiling fans are integral in reshaping and enhancing cooling efficiency for the future. Explore the intricate details that make cooling more effective and create the next level of super-efficient ceiling fans.

By: Dr. Sandeep Garg, Ashish Jindal, Anurag Bajpai, Arvind Tariyal, Syed Faraz, Shikha Saxena

In our journey through India's evolving energy landscape, we explored the transformative impact of super-efficient ceiling fans. Delving into the growth trajectory, we witnessed how strategic interventions and heightened awareness are pushing the boundaries of energy efficiency. As we transition into the next phase, let's review the key insights from our previous article. This will provide a solid foundation for our in-depth exploration into the pivotal components that are driving a revolution in the energy efficiency of ceiling fans.

In the previous article, we examined India's rising energy consumption, particularly in the building sector, driven by an increasing demand for cooling. Ceiling fans, constituting 30% of cooling energy, play a pivotal role. The India Cooling Action Plan targets a substantial reduction in cooling energy needs. The latest BEE Impact Assessment reveals a shift towards super-efficient fans. This sets the foundation for our ongoing exploration into the dynamic landscape of ceiling fan energy efficiency.

This article covers the innovations in Ceiling Fan Components for creating the next level of super-efficient ceiling fans.

Innovations in Ceiling Fan Components

In our pursuit for smarter and more energy-efficient solutions, our focus shifts to a vital component of every cooling space—the ceiling fan. Advances in Ceiling Fan components involvedly examines the fundamental elements driving the evolution of these commonplace devices.

i. Magnet Selection

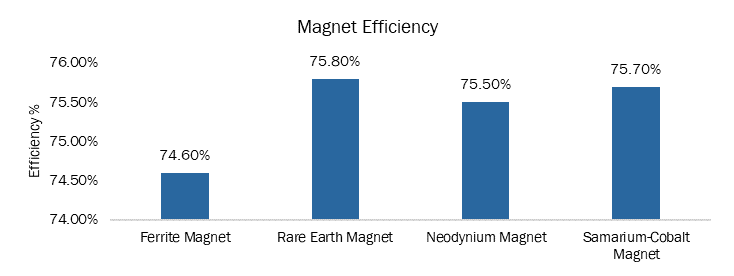

Magnets are the integral part of the ceiling fan. The selection of magnets in ceiling fan design is a key factor as it directly influences the efficiency, performance and energy consumption of the fan's motor. Efficiency and cost are carefully balanced in the magnetic selection process for motors. Evaluating the high trade-offs between high-performance rare earth and neodymium magnets, and the cost-effective ferrite and samarium-cobalt magnets (Figure 1), is essential.

- Rare Earth magnets are a type of magnet that includes the alloys of rare earth elements. They are known for their high magnetic efficiency, and are highly sought-after due to their exceptional magnetic properties.

- Neodymium magnets are the strongest type of permanent magnets, composed of neodymium, iron, and boron and are available commercially. These have a unique combination of high magnetic strength and excellent temperature stability.

- Samarium-Cobalt magnets are one of the types of magnets that are composed of samarium, cobalt and other elements. It is not as strong as Neodymium magnets, still offers high magnetic strength.

- Ferrite magnets are ferrimagnetic, meaning they are attracted by magnetic fields and can be magnetized to become permanent magnets. They have moderate magnetic strength, are resistant to corrosion, and have low manufacturing costs, i.e., they provide a cost-effective alternative.

Source: GreenTree Research

ii. Blade Design and Material Choice

Blades has a significant role in determining energy efficiency in ceiling fans, with studies emphasizing the influence of blade angle and material choice. Optimal outcomes are achieved through careful considerations.

Blade design is a key which influences the performance and efficiency of ceiling fans. Optimally designed blades enhance the fan's ability to move air efficiently, reducing the load on the motor and contributing to improved energy efficiency. The change in blade angle has a key impact on motor efficiency. Blade design in ceiling fans is typically classified based on various factors, including shape, size, and material.

The choice of material, including PVC, aluminum, and GFRP laminated composite, are crucial for enhancing energy efficiency, offering valuable guidance for designing future energy-efficient ceiling fans.

- Steel blades are durable, combined strength and design flexibility, but are heavy as compared to the other blades.

- PVC blades are the lightweight and cost effective, which reduces the load on the motor and contributes to the affordable fan options.

- Aluminum blade is durable, resistant to rust and also is the excellent conductor of heat that ensures longevity and performs well in high humidity.

- GFRP Laminated Composite is a strong, durable, and design-versatile due to glass fiber reinforcement. It combines strength and design flexibility, exhibits corrosion resistance, and ensures structural integrity.

The choice of blade material impacts the fan's efficiency, noise generation, aesthetics, and longevity. Manufacturers consider these factors while designing ceiling fans to provide an optimal balance of performance and durability.

iii. Controller

Ceiling fan controllers contribute to energy efficiency by being essential in regulating the fan's speed and operation. Efficiency enhancements in controllers involve strategies like reducing size and improving component quality.

Smaller controllers with fewer components minimize energy loss through resistance and heat generation; while high-quality electronic components result in improved performance, lower energy consumption, and increased reliability. Manufacturers embracing these strategies can craft energy-efficient ceiling fan controllers, aligning with energy-saving and sustainability goals. Overall, controllers optimize the fan's performance, ensuring efficient and controlled air circulation while minimizing energy consumption.

iv. Motor

As we move ahead, the future advancements in motor technology must strike a cost-performance balance aligning with energy efficiency goals. The selection is often a trade-off between performance and budget considerations.

The motor in a ceiling fan is a vibrant component, converting electrical energy into mechanical energy to drive the rotation of the blades. Its quality and efficiency directly impact the fan's overall performance and energy consumption. The motor design is optimized to deliver efficient air circulation while reducing power consumption. Based on the characteristics and applications, the motor is classified as:

- Induction Motor: This single-phase induction motor with permanent capacitor, is the most common type of motor found in ceiling fans. It operates based on the principle of electromagnetic induction, providing a cost-effective and reliable solution. Induction motor based ceiling fans are renowned for its strength, dependability, and affordability, but also consume very high power mostly near to 70 watts. The changes in their design are intended to make them energy efficient.

- Brushless DC Motor (BLDC): BLDC technology revolutionizes electric motors by employing a permanent magnet rotor and electronically controlled stator windings. The electronic commutation system in BLDC motors eliminates the need for brushes, resulting in reduced friction, wear, and the associated risks of sparks and electrical noise and also offer precise speed control. Furthermore, the absence of rotor windings minimizes energy losses, enhancing overall motor performance. This allows for accurate and smooth adjustment of the motor's rotational speed, making them well suited. Efficiency is a significant advantage of BLDC technology, where it consumes 28-35 watts of energy, in comparison with regular fans. So, they are 50-60% more efficient.

- Switch Reluctance Motor (SRMs): These provide an alternative option for ceiling fans, offering unique advantages that set them apart from the more commonly used BLDCs Motors. SRMs operate based on the principle of magnetic reluctance, utilizing the flow of magnetic flux through the path of least reactance. Unlike BLDCs, SRMs do not require permanent magnets in the rotor, which reduces maintenance cost and simplifies manufacturing processes. They consume nearly 50-60% less power than a regular fan, the fan developed so far consumes 34 W.

In essence, the motor is crucial for the fan's functionality, influencing both energy efficiency and overall effectiveness in providing air circulation and cooling.

As we conclude this exploration into the core components of energy-efficient ceiling fans, the journey continues with a focus on integrating procurement of invertor AC and Super Efficient Fans. Please connect [email protected] if you have any query.

Stay tuned for insights that shape the future of ceiling fan technology.