Saving Energy at Havells through ESCO..

Blog by - Jeyraj, Amit Singh, Pushpendra Kumar, Karthik, T M Shilpa

“...judicious and effective use of energy to maximize profits (minimize costs) and enhance competitive positions” _ Cape Hart, Turner and Kennedy

Based on the manageability of cost or potential savings in each of the three operating expenses – energy, labor, and materials – energy is invariably the highest-ranking component, and as a result, energy is a strategic area for cost reduction.

There was impending discussion of reducing the rate of power consumption at the Havells (Standard Plant and Plant Unit 1 & 2) located in Haridwar, which consumed 3124400 kWh/year at a cost of Rs.1.86 crores and 5941770 kWh/year at Rs.3.51 crores respectively.

As a result, GreenTree Global has made recommendations to assist the organization in savings of up to 68% or 76%. In line with the company's vision to enhance future projects and help spread knowledge, this report will provide you with insights provided to Havells regarding the savings it achieved every year.

Energy Audit Report for Havells (Standard Plant and Plant Unit 1&2 …

Performance Evaluation Records:

As per the Purchase Power Profile:

• Havells India Ltd. draws power from UPCL through dedicated feeder at 11 KV.

• In Standard Plant premises, two transformers are installed, one for each unit having a capacity of 1200 kVA and 2000 kVA and Plant Units 1 & 2 having a capacity of 1000 kVA to reduce the voltage from 11 KV to 433 V.

• The sanctioned load of the plant is 750 KVA.

As per the Electricity Bill profile:

• The audit team has reviewed the last one year electricity bill available from the plant from September 2017 to August, 2018.

• The consumption of electricity during peak hours, i.e. around morning and evening peak hours (at higher rate of Rs.6.3 / kWh) accounts for 25% of total consumption.

As per the Total Electrical Consumption profile:

• For Standard Plant : The total electrical unit consumption of the plant (electricity through grid + electricity generated by diesel generator) for the last 1 year is around 32.3 lakh units and the total electricity cost comes to be Rs.214 lakh.

• For Plant Unit 1 & 2 : The total electrical unit consumption of the plant (electricity through grid + electricity generated by diesel generator) for the last 1 year is around 19.4 lakh units and 43.7lakh units respectively for unit1 & unit 2 and the total electricity cost comes to be Rs.131 lakh and Rs.295 lakh.

Recommendations:

Shifting of Non-Operational Load from Peak Hours to Off-Peak Hours –

It is recommended to shift the non-operational loads such as domestic load, pumping load, etc. i.e. the peak hour load to off-peak hours which is at electricity tariff rate of Rs.3.57 / kWh.

Roof top Solar Energy Generation –

It is estimated that the gird connected system has an electrical unit generation potential of 15.3 lakh kWh/year, which would require an investment of Rs.461 Lakhs and simple payback period of 42 months if tax rebate can be claimed and 55 months without tax rebate.

Power Factor Profile -

The power factor of an AC electrical power system is defined as the ratio of the real power flowing to the load, to the apparent power in the circuit.

• For Standard Plant - It was observed from the above figure that the power factor of 1000 kVA transformer is varied in range from 0.933 to 0.992 with an average power factor of 0.975

• For Plant Unit 1 & 2 - It was observed from the above figure that the power factor of 1250 kVA transformer is varied in range from 0.906 to 0.994 with an average power factor of 0.988.

• Recommendation - It is recommended to improve the average power factor of the Plant and operate at power factor near to unity, i.e. operating at power factor of 0.99 from the existing power factor of 0.988.

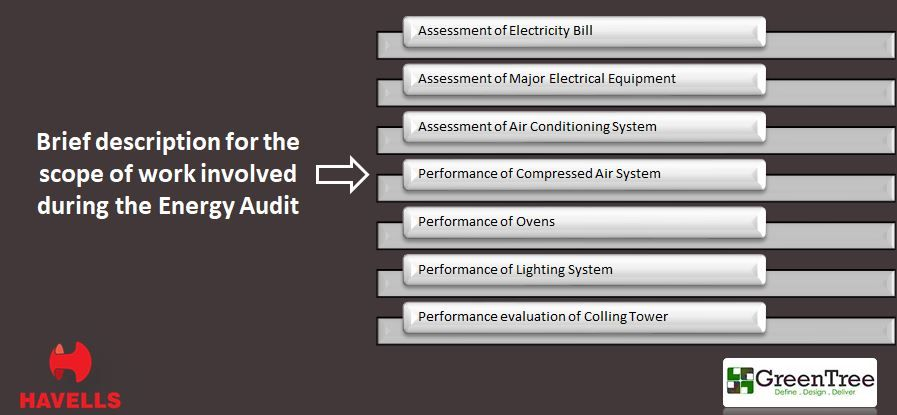

Compressed Air System –

• For Standard Plant – Savings in energy by reducing the pressure from 7.9 kg/cm² to 6.5kg/cm²

For Plant Unit 1 & 2 - Savings In Energy By Reducing The Compressed Air Discharge Pressure Set Point From 7.3 kg/cm² to 6.0 kg/cm².

Lighting Systems –

The plant has taken active steps for energy conservation in lighting systems. The plant has gone for mass replacement of the FTL’s with LED’s. It is recommended to install light pipes to further reduce the present energy consumption.

Salutations

With the help of an energy audit, Havells India Limited, a leading Fast Moving Electrical Goods (FMEG) Company, has managed to lower energy consumption and improve the life span of equipment's and comfort of facility staff significantly. By achieving such targets, various manufacturing unit can reduce the pressure on our existing power grid and ensure that the NDC's target will be met on time.